HPL grinding wheels rely on premium-grade CBN crystals fixed with durable, porous, intrinsically lubricated bonding matrix to allow faster grinding of difficult materials without sacrificing quality due to wheel loading and/or part burning.

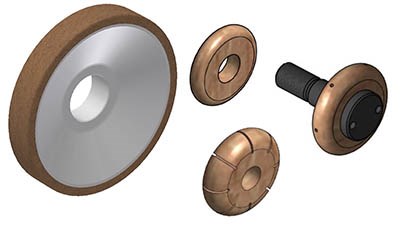

Meister Abrasives’ high-performance lubrication (HPL) grinding wheels rely on premium-grade CBN crystals fixed with durable, porous, intrinsically lubricated bonding matrix to allow faster grinding of difficult materials without sacrificing quality due to wheel loading and/or part burning.

Meister HPL wheels contain a lubricant that is intrinsic to the bonding matrix chemistry and is released uniformly as the wheel breaks down. Wheels manufactured with this technology minimize friction from bond/work piece interactions, minimize heat generation, and deter the onset of metal loading into the bond structure.

Grit retention and lubricating properties of the bond make it possible to use high concentrations of premium grade CBN crystals that in a standard bonding matrix would generate too much pressure and heat.

The properties of the intrinsically lubricated wheels address a wide range of problems including: burning of parts, wheel loading, excessive wheel wear due to heat related issues, and quality issues due to temperature sensitive materials.

Applications for HPL abrasive technology:

Deep bore grinding with limited coolant access

Blind-end bore grinding such as lash adjusters, tappets

Heavy-stock form grinding applications

Creep-feed grinding of tool steels, superalloys

High stock removal out-of-round grinding for punches

Applications where the concentration of oil and lubricant are low or coolant flow is impeded, as in deep bores

HPL (High Performance Lubrication) CBN grinding wheels are available for both internal and external grinding with mesh sizes ranging from 60 to 1200.