In order to ensure the grinding efficiency of rough grinding, we need to pay attention to the following factors.

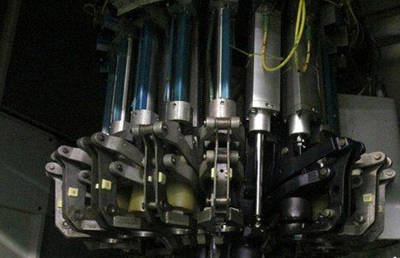

At present, diamond tool lapping machines are widely used in production due to its structure and its simplity. Rough grinding of diamond tools can remove more quantity of diamonds as soon as possible, but also can effectively ensure the surface quality that won't produce big scratches and avoid large defects appearing cutter blade, or it will cause great difficulties. Therefore, in order to ensure the grinding efficiency of rough grinding, we need to pay attention to other factors.

A, The grinding direction

The grinding direction should be a good grinding direction of diamond crystal. If the grinding direction deviates, it will bring down the grinding efficiency greatly. If the grinding direction is wrong, it will occur the phenomenon of skid, vibration, noise and so on. So it is important to find a good grinding direction. If the direction is right, you can feel smooth, normal, and sometimes you can see tiny sparks of light yellow or light blue. Then the grinding will become very smooth, and the grinding efficiency will also be higher.

B, The grinding rate

To get more grinding removal quantity, we must strive to improve the line grinding speed, but increasing the line speed has a certain limit due to objective conditions, sowe should increase the diameter of the grinding disc, or improve the rotate speed. Increasing the diameter of grinding disc is the shortcut to increase the line speed, but the unlimited diameter will make lapping machine volume increased, which will be not conducive to the loading and unloading of grinding disc.

C, The load applied to the diamond

Increasing the load of diamond can obtain large grinding removal quantity, which can make the grinding efficiency improved. Usually, the load should not be too large, otherwise it will cause excessive grinding removal quantity and great grinding heat, which will affect the surface quality of diamond. Sometimes, it may make diamond appear crack, breakage or oxidation.

D, Diamond micro powder particle size

Using coarse grained diamond micro powder can improve the grinding efficiency. But if you want to make the surface roughness of diamond increase, you can begin using coarse grain size of diamond micro powder, and later you can change to use smaller particle size diamond micro powder which will help you get a better grinding surface quality.