Do you know about dispersion technology of nano diamond? This article will tell you in detail.

Nano diamond has poor stability in medium and is easy to cause obvious agglomeration, so that it is severely restricted in the process of application. That is to say, the key technology of the preparation of nano diamond polishing liquid is a long-term and stable dispersion of nano diamond in medium and the uniformity of particle size. This is a worldwide technical problem.

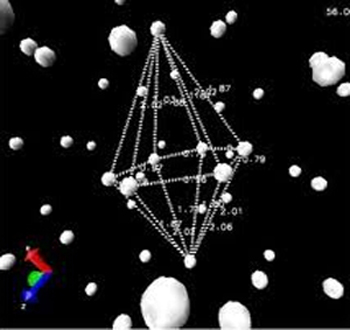

The particle size of nano diamond dry powder is an average of 2 microns, and the surface of nano diamond contains a large number of organic functional groups that are mainly OH (hydroxyl), -C = O (carbonyl), -COOH (carboxyl) and some nitrogen groups, whose size can reach 10% ~ 25% of the particles surface. These reactive oxygen and nitrogen active substance can react with many organic compounds, which provides the basis for the dispersion of nano diamond in oil or water.

Dispersion technology of nano diamond can be divided into physical dispersion and chemical dispersion. Physical dispersion can be also divided into the ultrasonic dispersion, mechanical stirring dispersion and mechanical grinding. Chemical dispersion can be divided into and chemical modification dispersion and dispersant dispersion. The dispersion process of nano diamond polishing liquid is to make nano diamond aggregate in the polishing liquid in the original monomer and diffuse in the liquid phase.

Dispersion process mainly includes two steps:

Firstly, the particles wet in the liquid phase.

Secondly, the primary particles are stably dispersed and do not have agglomeration or make formed agglomeration cracked into smaller original monomer particles.

Some industry experts in our country have explored stable dispersion technology and its mechanism of nano diamond in aqueous medium. It is considered that the mechanical chemical process can be carried out on the diamond surface modification. People can make full use of high shear mixing and high-energy ultrasonic vibration and other mechanical force, and the coordination effect of polymer surfactant, effectively to crush nano diamond and make new surface modification in the process of crushing, adjusting the hydrophilic and hydrophobic of particle surface and realizing the stable dispersion of nano diamond in the medium.

Based on the results of this research, nano diamond has got surface modification by using silane coupling agent called KH-570 and polymer JQ-3, and obtained the average particle size of 51.7nm colloidal solution with ultrasound as a means of dispersion, dispersing in ethanol. Two kinds of polymer dispersant can improve the dispersion and stability of nano diamond in ethanol, and lay the groundwork for producing domestic oily polishing liquid.