Every kind of cutting tool materials will appear some exceptions in the process of developing, so we must explore and research constantly. Each material has their different features, and we should choose reasonable processing methods in use according to the properties of the tools and processed materials and the processing conditions.

It is well known that diamonds are the hardest substance in the world. It is ideal as cutting tool material. That's why it is widely used now. But it has affinity with black metal, and the graphitization will happen about 700 ℃, which makes diamond wear accelerated, so it is only suitable for cutting non-ferrous metals and non-metallic materials.

People have been trying to break the box, such as the LLNL laboratory of United States once cut black metal directly in the environment filled with carbon, which has certain effect; Harbin institute in our country used liquid nitrogen spray to cut ferrous metals in cryogenic, which also obtained the certain effect. Recently, some people think that diamond containing a certain amount of boron may cut black metal, which is likely to be a breakthrough in the near future.

The cutting tools of superhard material coatings appear earlier than the ceramic coating, but there are still many problems to be solved, especially the strength of the glue relay, which directly affects the service life of cutting tools. There are also the same problems in the ceramic, such as the clean processing of cutting tool before the coating. And it does not allow edge annealing and burrs in the cutlery grinding of cutting tool. We can use the coating solution to solve but it remains to develop further in terms of superhard coating.

The birth of ceramic coating technology is a major development of cutting tool material, and another breakthrough of superhard material coatings makes almost all of the cutting tools moving to a more ideal field.

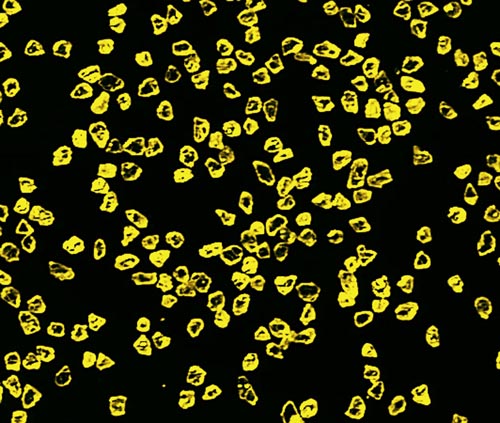

PCD and PCBN cutting tools are common in the current application, whose development of technology still be taken seriously. For example, foreign products can directly cut into the specified shape with electric spark linear cutting in the manufacturing, but domestic blank can only be cut their carbide parts firstly, and then cut the rest. Generally, the surface roughness of this kind of cutting tool can achieve is lower, but the fine-grained blade of American GE company can close to the mirror, whose main reason is the ultrafine grain size. With the interface increasing, it can obtain more smooth cutting edges.

The synthesis of thick film diamond is a breakthrough of cutting tool material, which will provide more possibilities to replace natural diamond in the current application in the field of ultra-precision machining. It is not only because of its performance close with natural diamond, but also its low cost. For diamond deposits in sparsely populated countries, it shows good prospect. The substrate of diamond deposition must be carefully cleaned before deposit. If it is cemented carbide, especially the cobalt-based cemented carbide, it affects the nuclear density of diamond synthesis. If it is low density, the deposition quality will be significantly worse, and the coating bonding force is also low. Therefore, you have to take the corrosion solution to remove cobalt on the surface.

Synthetic monocrystal diamond of large particles have achieved great breakthroughs, but the cost is still high and it still needs to be developed. In a word, the development of superhard material will bring huge change for machinery manufacturing and will undoubtedly make greater contribution in the 21st century.