Corundum is a crystalline form of aluminum oxide and is found in various different colors, most of which are generally referred to as sapphire, which may be an attractive alternative to other translucent materials like glass or polycarbonate.

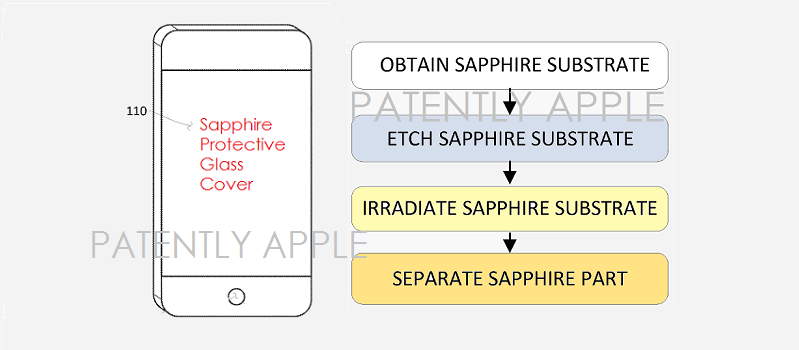

A little under 10 months' ago Apple's one-time Sapphire supplier GTAT shockingly filed for bankruptcy. Countless problems in the manufacturing process failed to produce the sapphire that Apple wanted to use for the iPhone 6's cover glass. Today the U.S. Patent & Trademark Office published a patent application from Apple that reveals a very sophisticated method to manufacture sapphire parts, and in particular to using a laser and more than one gas medium to cut a sapphire substrate and to produce a sapphire part. The sapphire part was to be for a protective cover for a portable electronic device. Whether Apple's invention will surface in a partnering plant or simply be scrapped is unknown at this time.

Corundum is a crystalline form of aluminum oxide and is found in various different colors, most of which are generally referred to as sapphire. Sapphire is a hard and strong material with a hardness of 9.0 on the Mohs scale, and, as such, is capable of scratching nearly all other minerals. Because of its hardness and strength, sapphire may be an attractive alternative to other translucent materials like glass or polycarbonate. However, due to its brittle nature, sapphire is susceptible to dramatic strength reductions as a result of small defects in the surface or edge of the part. It is generally desirable to minimize small defects that may occur during manufacturing to produce a sapphire part that is durable and long lasting.

Manufacturing a near defect-free sapphire part may present unique challenges. The strength of a brittle material, such as sapphire, is limited due to flaw population on the surface or edges of the part. An inconsistent or inadequate surface or edge finish can lead to the propagation of micro cracks and result in a weakened part.

Traditional translucent materials like silicate glass are able to be chemically strengthened to a significant depth to minimize the effect of these flaws, but on extremely hard materials such as sapphire, a similar process is not readily available. Sapphire's hardness makes cutting and polishing the material both difficult and time consuming when using conventional processing techniques. Further, conventional processing tools, such as cutters, experience relatively rapid wear when used on sapphire. This further increases the resource demand when surface finishing sapphire parts.

In general, there is a need for a system and method for producing sapphire parts having minimal micro-defects on the edges and surface of the part resulting in improved strength and to reliability over time. There is also a need for a system and method for producing high-quality edge cuts on sapphire parts in a rapid, repeatable fashion while using an efficient amount of resources.