With the effort of Japan Sumitomo and the Element Six, the Method of high temperature and high pressure to produce synthetic monocrystalline diamond has gradually replaced natural diamond in various application fields since 1990.

With the effort of Japan Sumitomo and the Element Six, the Method of high temperature and high pressure to produce synthetic monocrystalline diamond has gradually replaced natural diamond in various application fields since 1990.

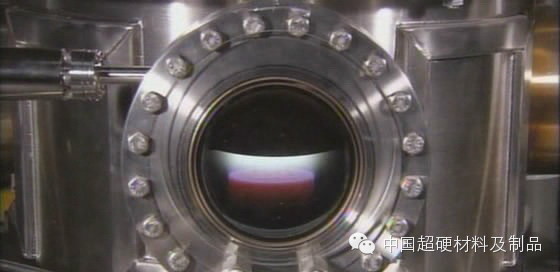

Before 2013, most synthetic monocrystalline diamond was produced by the method of high temperature and high pressure, while with the development of synthetic monocrystalline diamond by CVD technique, CVD monocrystalline diamond has become a kind of synthetic monocrystalline diamond.

The particle size of high temperature and high pressure synthetic monocrystalline diamond cutter blanks material is often smaller than 6mm in diameter out of the cost, but the synthetic monocrystalline diamond by CVD method particle size can reach 12mm in diameter at most, which can remedy the defect of the synthetic monocrystalline diamond formed under high temperature and high pressure.

Currently, the conventional specifications of CVD monocrystalline diamond includes: 12×3×1(mm); there are also 11mm, 10mm, 9mm, 5mm, etc. As to 4mm or even smaller CVD monocrystalline diamond cutter blanks materials, since the price of synthetic monocrystalline diamond formed by high temperature and high pressure is inexpensive, CVD monocrystalline diamond cutter blanks materials have no specifications that are smaller than 4mm.

According to the experience of diamond cutting tool manufacturers, synthetic monocrystalline diamond cutting tools by CVD method have a longer service life than that of synthetic monocrystalline diamond formed by high temperature and high pressure method. So CVD monocrystalline diamond cutting tools are widely used in some high-end processing fields.

Author: Liwei Chu

Copyright: iAbrasive.com--Abrasives & Diamond Tools Market products