Zhengzhou Zhengtong Abrasive import&export Co., Ltd

Zhengzhou Zhengtong Abrasive import&export Co., Ltd

Zhengzhou Zhengtong Abrasive import&export Co., Ltd

Zhengzhou Zhengtong Abrasive import&export Co., Ltd

[

Henan,

China (Mainland) ]

Ceramic Bead Blasting media in 3C industry for deburrs and blast finish

ZrO2 60-68% Ceramic Beads B20 - B400 Surface finish Blasting Media

ZrO2 95% Yttria stabilized Zirconia Beads Grinding Media For Color Paste Coating / Painting

Micro Powder White Aluminum Oxide Abrasive 240# - 1200# Super Fine Grinding / Polishing

Al2O3 62.% Min. Black Aluminum Oxide Abrasive grain , Aluminium Oxide Blasting abrasive

Henan, China (Mainland)

Zirnano

B20-B505

Fine

Other

Ceramic Beads Blasting Media

ZrO2 60-66%, SiO2 25-30%, Al2O3 7-13%

Melting Method

2.3g/cm3

3.85g/cm3

700HV

Ton

1

10 days

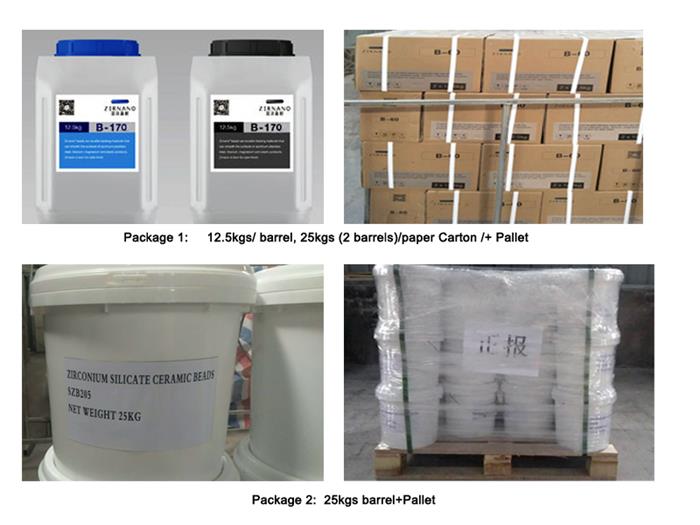

2*12.5kgs barrels+Paper Cartons Or 25kgs Barrels +pallet

3000 / Year

L/C, D/P, T/T

ZrO2 62-68% Ceramic Beads B20 - B400 Surface finish Blasting Media

The ceramic beads is made from zirconium sand, melting and blending in the high temperature mine heat furnace, then made to micro beads, normal size from B20-B505 with features of good elasticity, low abrasion wear, long worklife and easy to clean.

It is one of the best cost effective sandblasting media/sandblasting abrasive, mainly used for 3C products, golf balls, medical instrument, kitchenwares sandblasting to deburr and surface finish, molds cleaning and aerospace & automotive industry shot peening, etc.

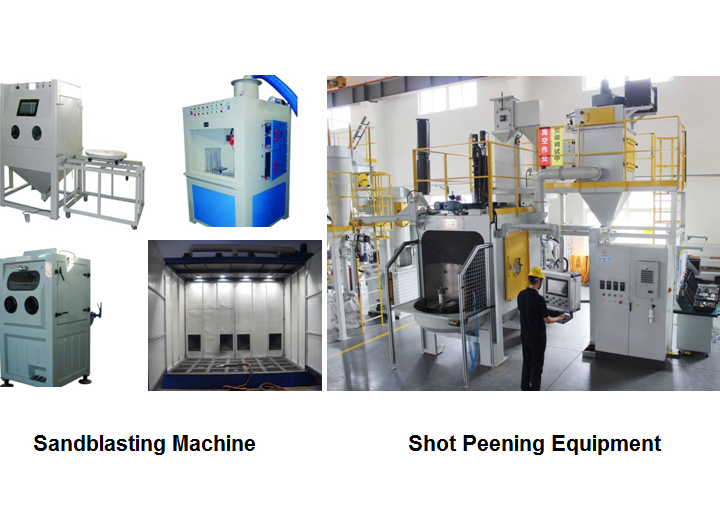

Applicable sandblasting machines including Manual & Automatic sandblasting machine, Open type sandblasting machine and Sandblasting machine room, and shot peening equipment, etc.

Chemical Index:

ZrO2: 60-68%

SiO2: 25-30%

Al2O3: 7-13%

Physical Index

Processing: Melting

Bulk Density: 2.3g/cm3

True Density: 3.97 g/cm3

Vickers Hardness: 700 kg /mm2

Sizes

Grit size B20 B30 B40 B60 B80 B100 B120

μm 600-850 425-600 250-425 125-250 180-250 125-180 63-125

Grit size B125 B170 B205 B400 B505

μm 0-125 45-90 0-63 30-63 0-63

Grit size Z850 Z600 Z425 Z300 Z210 Z150 Z100

Microns 850-1180 600-850 425-600 300-425 210-300 150-210 100-150

Special sizes can be customized

High efficiency

With high hardness, long life and good elasticity, suitable for the complicated structure,without damage to the surface of the workpiece, eliminate the stress and improve the fatigue life of the workpiece.

High cost performance

Compared to glass beads, it has higher cleanliness, can prolong the service life 30-50 times. Compared to steel beads, it has superior smoothness, can prolong life 3-5 times. It ‘s also recyclable,and can reduce the refueling times, improve working efficiency.

Environmental protection

Not easy to break during sandblasting process, no dust, clean, and no hidden danger of silicosis, it is harmless to the human body.

l In Sandblasting

1) 3C products - Sandblasting Finishing

Alloy shell, middle frame and built-in parts of computers, mobile phones, cameras, etc. - sandblasting finishing

Clean burrs to form film-light decorative or fine reflective surface, on alloy workpiece such as mobile phone to achieve different reflection or matte.

2) Kitchen Industry-Sandblasting finishing

Stainless steel cutlery and kitchen utensils sandblasting finishing

3) Golf club - Sandblasting finishing

Golf club & ball head alloy surface treatment Sandblasting finishing

4) Casting and forging parts, welded parts, heat-treated parts - Sandblast Cleaning

Clean all the dirt on the surface of the alloy workpiece, micro burrs, improve the flatness and smoothness of the workpiece, and expose to uniform metallic color, achieving smooth and non-reflective requirements on surface.

5) Pipeline - Sandblast Cleaning

Metal pipes such as copper pipes and steel pipes are cleaned and polished on the inner and outer walls.

6) Molds - Sandblast cleaning

Cleaning of molds of glass bottles, tires, etc., rust, dirt and impurities.

7) Electroplating, painting, anode-Surface Pretreatment

Electroplating, painting, anode, Teflon, rubber, plastic, traversing, metal, spray welding, gold plating, titanium plating, etc., to remove dirt and increase product surface adhesion.

8) Hardware parts - Sandblasting to improve lubrication conditions

It can produce uniform and fine uneven surface on the surface of the part, so that the lubricating oil can be stored, improve the lubrication condition and reduce the noise.

l In shot peening

1) Aerospace industry-Shot Peening

Suitable for aerospace engine components, aircraft landing gear, gear transmissions, aero-engine blades, aircraft wing-shot peening

2) Automotive industry-Sandblasting reinforcement/ Shot Peening

Suitable for gearbox gears, automotive aluminum hubs, piston components/shock absorbers, engine crankshaft sandblasting reinforcement/shot peening

3) Machinery, Medical Instrument - Sandblast finishing/shot peening

The overall sandblasting and polishing, finishing, restore the natural color of the metal, enhance the visual effect and texture, and also shot peening reinforcement to improve its worklife.

l In sandblasting

Manual sandblasting machine

Automatic sandblasting machine

Open type sandblasting machine

Sandblasting machine room

l In shot peening /shot blasting

Pneumatic shot blasting machine

Centrifugal shot blasting machine

CNC shot peening equipment

Wet shot blasting equipment

Free Samples -1kgs

Different blasting workpieces, Different requirements for ceramic beads.

Our factory can provide consult solution, suggest the ceramic beads sizes according to the workpiece you handle and provide 1kgs ceramic beads samples for free.

OEM customize same ceramic beads with your samples or requirements.

Our factory has our own test lab., with high precision chemical and particle size detection instruments. You can send ceramic beads samples, then we will test and analysis it and customize same ceramic beads with your samples or according to your customer requirements.

Quality Guarantee

Guarantee our ceramic beads has no quality problems, and in case any problems are found,

We accept return and/or exchange.

No matter you’re the end users, blasting service suppliers, sandblasting equipment dealers or ceramic beads and other blasting abrasive distributors, welcome to contact us. More details of ceramic bead blasting, updated prices and samples will be available.

Caroline Cui