Henan Shengchuang Super Hard Products Co., Ltd

Henan Shengchuang Super Hard Products Co., Ltd

Henan Shengchuang Super Hard Products Co., Ltd

[

Henan,

China (Mainland) ]

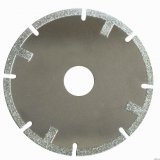

Metal bond diamond cutting disc for cutting semiconductor materials

Metal bond diamond cutting disc for cutting monocrystalline silicon

TSP diamond cutter,1.5x1.5x5, for oil drilling bits,USA market

5 blades pdc drill bit for oil drilling(julia#kosuperhard.com)

360 Round shape PCD Cutting Tool Blanks,PCD cutting blanks(julia@kosuperhard.com)

2.0mm synthetic monocrystalline diamond for singal crystal diamond tools

2.0mm synthetic monocrystalline diamond for diamond cutting tools and grinding wheels

Pcd & CBN grinding wheels, Pcd/CBN diamond tools, super abrasive tools

Vitrified Bond Diamond Grinding Wheels for PCD ,PCBN,Hard Alloy

ceramic grinding wheel for natural diamond polishing and grinding

Henan, China (Mainland)

KOSUPERHARD

pcd blanks

PCD

Rectangle

Drilling Bits

Pieces

2

USD 10.000 - 199.000

shenzhen,shanghai

plastic box,carton box

Yes

200000 / Month

T/T, Western Union, MoneyGram, Other

Polycrystalline Diamond (PCD)

Composition of PCD (Polycrystalline Diamond)

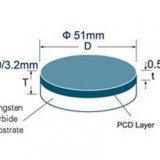

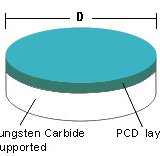

Polycrystalline Diamond (PCD) is a synthetic diamond product that is produced by sintering together selected diamond particles with a metal matrix using sophisticated technology. The diamond and matrix, when sintered together under high temperatures and pressures, creates a PCD tool blank that is high in uniform hardness and is abrasive resistant in all directions. This PCD diamond layer is then bonded to a tungsten carbide substrate, which provides strength and a brazable base to permit bonding to other metals.

Polycrystalline tipped tools are exceptionally resistant to wear compared to tungsten carbide or ceramic tools. In certain applications, PCD tool life can exceed carbide cutting tool life 50 to 100 times.

In certain applications, polycrystalline tipped tools have several advantages over natural diamond.

Shock Resistance

PCD is more shock resistant over natural diamond because of its random orientation structure of the diamond particles, and is backed by a carbide substrate.

Consistency

PCD is more constant in wear. Again because of the random orientation of diamond particles. Natural diamond is a single crystal in nature and has soft and hard grains. Depending on the shape of the natural diamonds and the tool being manufactured, it is sometimes not practical to have the hardest grain on the cutting edge.

Availability

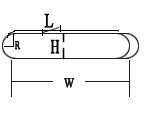

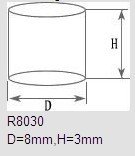

PCD is readily available in a large variety of shapes and sizes. Discs as large as 60 mm in diameter are now available. Natural diamond is limited to what is formed in nature. Diamond, even with only an 8 mm long cutting edge is extremely difficult to find and is very costly.

Flexibility

PCD is a conductor. This allows us to routinely produce complex form tools and grooving tools with our wire EDM machines. Such tools are impossible to produce in natural diamond.

Cost

PCD blank costs are considerably lower than the cost of natural diamond stones, and the availability of different shape PCD blanks reduce manufacturing cost significantly. The longer of a cutting edge required, the larger the savings of PCD over natural diamond due to the rarity of larger stones.

Natural diamond and PCD diamond compliment each other. Natural diamond is denser than its PCD counterpart and consequently can be polished to a keener cutting edge.

Natural diamond is best suited to produce very fine finishes and precise tolerances as required in the manufacturing of jewelry, plastic contact lens, computer memory discs, and aluminum camera parts. See natural diamond tools.

Polycrystalline diamond tooling can be used in a wide range of machining operations such as milling, grooving, turning, facing and boring. They are recommended for machining nonferrous metals and abrasive non metallics.

Any need pls feel free to contact julia#kosuperhard.com