Henan Yeda New Material Technology Co., LTD

Henan Yeda New Material Technology Co., LTD

Henan Yeda New Material Technology Co., LTD

Henan Yeda New Material Technology Co., LTD

[

Henan,

China (Mainland) ]

Anti-slip Construction material Black Fused Alumina 0.4-1mm,1-3mm for Wear-resisting Pavment

Good Self-sharpness Synthetic Aluminum Oxide Black Fused Alumina F24 for Boned Abrasives

Better Self-sharpening Black Aluminum Oxide Fused Alumina P12-P320 For Coated Abrasives

Synthetic Black Aluminum Oxide P40 / P60 / P80 / P120 For Making Sand Belts

Moderate Hardness Black Aluminum Oxide Artifical Corundum F100#-F400# for Fiber wheels

Good Self-sharpness Synthetic Aluminum Oxide Black Emery to Make Sand Belts Sand Paper

Synthetic Aluminum Oxide Black Fused Alumina 1 - 3 mm 3-5mm for Anti-slip Aggregates

Medium Hardness Aluminum Oxide Black Fused Alumina F12-F240 for Polishing Stainless Steel

Fast Cutting Force Black Fused Alumina Synthetic Aluminum Oxide F24-F60 for Bonded Abrasives

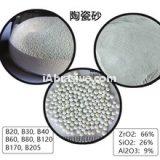

Zirconia Silicate Beads for steel pipe cleaning & mould cleaning

black fused alumina mixed with brown fused alumina for Cutting discs

black fused alumina mixed with brown fused alumina for Cutting discs thin wheel

Bonded tools thin wheel black fused alumina mixed with brown fused alumina

Resin cutting discs raw materials manufacturer Black Fused Alumina

Yeda black aluminium oxide mixed with brown aluminium oxide for making fiber wheel

Yeda high quality black fused alumina for wear resistant materials 1-3mm

Yeda black aluminium oxide for wear resistant materials 1-3mm

Yeda black aluminium oxide for wear resistant anti skid road 0.4-1mm

Yeda black aluminium oxide for Anti slippery surface 0.4-1mm

Black Fused Alumina for wear-resistant anti-slippery surface

Henan, China (Mainland)

Yeda

F

Grain

Angular

FEPA

F12-F220

Bonded Abrasives

1.68-1.22 g/cm3

3.5g/cm3

Black

2000-2200g/cm3

Ton

1

USD 480.000 - 530.000

Tianjin,China

3-10 days after order confirmed

25kg Bag+ Ton Bag, 25kg Bag+Pallet

30000 / Year

L/C, T/T, Western Union, MoneyGram, Other

Good Self-sharpness Synthetic Aluminum Oxide Black Fused Alumina F24 for Boned Abrasives

1. Product Description of Synthetic Aluminum Oxide Black Fused Alumina

Black fused alumina also belongs to the electric corundum group,it is made by high iron bauxite,high alumina

bauxite and iron oxide as main raw materials,then smelted in the electric arc furnace completely,then finally

made into different grit size after different processes of cooling,crushing,screening etc.

It has the characteristics of moderate hardness,good self-sharpness,strong cutting force,not easy to burn the

treatment surface.

In addition,its price is 40 percent cheaper than the one of brown fused alumina, so it could partically replace

brown fused alumina in many applications such as boned abrasives.

2. Main Technical Index of Synthetic Aluminum Oxide Black Fused Alumina

| Commodity | Usage | Main Chemical Index | |||

| Al2O3 | Fe2O3 | SiO2 | TiO2 | ||

| Black Fused Alumina | Making Bonded Abrasives | ≥60 | 6-12% | ≤25% | 2-4% |

| Main Physical Index | |

| Color | Black |

| Crystral Structure | Trigonal |

| Shape | Block,Sharp |

| Mohs Hardness | 8.0-9.0 |

| Vicker Hardness | 2000-2200kg/mm2 |

| Specific Gravity | ≥3.5g/cm3 |

| Bulk Density | 1.68-1.22 g/cm3 |

| Crushed Method | Barmac,Ball Mill |

| Grit Size |

F12-F220. |

| Product Standards | GB/T,FEPA etc. |

3. Why Black Fused Alumina is Suitable for making resin cutting discs?

Firstly,black fused alumina is one kind of corundum made by special process, having its own chemical composition

and crystallization condition compared with the second grade brown fused alumina, it has the more stable quality

to ensure the final products’ stability in performance;

Secondly,When mixing 30-50% ordinary black fused alumina with brown fused alumina to make resin cutting discs,

it will finally enhance the cutting discs’s sharpness and smooth finish , ease the surface discoloration, and feel more

stable when actual operation.

Thirdly,it will greatly reduce the overall production cost because black fused alumina price is 40% cheaper than the

one of brown fused alumina.

Fourthly,that application has been successfully used by Saint-gobain Group for over 10 years , now most famous

bonded abrasives plants is also widely using it.

In addition,Black fused alumina is also used in the following applications of

Coated abrasives: sandpaper,sandbelts and flap wheels;

Polishing stainless steel tableware;

Sandblasting media for surface decontamination,pipeline cleaning,hull-rust and Jean cloth

sandblasting;

Anti-slip aggregates in high traffic areas,aircraft runway, roads,bridge,parking floor etc.

Polishing wax;

Refractory materials.

4. How to use Black Fused Alumina to make resin cutting discs mixed with Brown Fused Alumina?

Generally speaking,when mixing black fused alumina with brown fused alumina to make resin cutting discs,

it is suggested to maintain or slightly reduce the original coarse grains of brown fused alumina , then use

30-50% black fused alumina to replace one or several fine grains of brown fused alumina according to the

original formula. It is also available to add about 5% finer grains(such as F60+70#, F70#) of Black Fused

Alumina when making large resin cutting discs,which will significantly improve the surface flatness and durability.

It is only a simple method for reference,people are able to find the right method according to their actual demands.

5. Why Choose Us?

China Largest Black Fused Alumina Manufacturer,over 20 years production experience;

Occupies more than 60% Domestic Black Fused Alumina marketing;

The Stable Supplier of Saint-gobain Group and Forsoc Group etc.

Certificated by ISO9001,ISO14001.

Anti-slip Construction material Black Fused Alumina 0.4-1mm,1-3mm for Wear-resisting Pavment

Good Self-sharpness Synthetic Aluminum Oxide Black Fused Alumina F24 for Boned Abrasives

Better Self-sharpening Black Aluminum Oxide Fused Alumina P12-P320 For Coated Abrasives

Synthetic Black Aluminum Oxide P40 / P60 / P80 / P120 For Making Sand Belts

Moderate Hardness Black Aluminum Oxide Artifical Corundum F100#-F400# for Fiber wheels

Good Self-sharpness Synthetic Aluminum Oxide Black Emery to Make Sand Belts Sand Paper

Synthetic Aluminum Oxide Black Fused Alumina 1 - 3 mm 3-5mm for Anti-slip Aggregates

Medium Hardness Aluminum Oxide Black Fused Alumina F12-F240 for Polishing Stainless Steel

Fast Cutting Force Black Fused Alumina Synthetic Aluminum Oxide F24-F60 for Bonded Abrasives

black fused alumina mixed with brown fused alumina for Cutting discs