Foshan Senta Abrasives Co., Ltd

Foshan Senta Abrasives Co., Ltd

Foshan Senta Abrasives Co., Ltd

Foshan Senta Abrasives Co., Ltd

[

Guangdong,

China (Mainland) ]

Zhejiang, China (Mainland)

Kingsba

KS-T41-100116F2-S

Combination

100/102mm (4'')

Abrasive Disc

100*1.0*16mm (4")

16MM

60#-150#

Black

4 , 5 , 6

P-T

Mixed Grain,single crystal corun

30 days

Pieces

25

Guangzhou/Foshan/Shenzhen/HongKong

25pcs packed 1 inner box , 800pcs packed 1 carton.

Yes

1000000 / Month

L/C, D/A, D/P, T/T, Western Union, MoneyGram

1. Cutting disc China

2. Visible double nets

3. Resin bonded

4. Quick and sharp

5. ISO9001, EN12413

Material:

Hard stone concrete, poroton, sand lime-bricks, refractory stones, concrete tiles

terrazzo, porcelain,ceramics,abrasive,Bond, mixed Grain,single crystal corundum ,etc.

|

Abrasive type code |

A: aluminum oxide |

|

C:silicon carbide |

|

|

Z:zirconia alumina grain |

|

|

ZA:zirconia alumina grain & aluminum oxide |

|

|

AC:aluminum oxide & silicon carbide |

|

|

WA:white corundum |

|

|

Grit |

Coarse :16-24# |

|

Medium:30-60# |

|

|

Fine-medium:70-220# |

|

|

Hardness |

Soft: A to Z |

|

Medium:H to K |

|

|

Hard: P to S |

|

|

Very Hard: T to Z |

|

|

Bond |

BF : Resinoid bond |

|

Fibre=Reinforced , woven or nonwoven |

Type 41 Flat Wheels for Cutting

Symbol of Construction Designation

| Figure | Structure | Remark |

| a-v-a | single net | |

| v-a-v | double nets | |

| a-v-a-1/2v | one and half-net | |

| 1/2v-a-v-a-1/2v |

one net inside and 2 half-net outside |

|

| a-v-a-v |

double-net (one inside and one outside ) |

............................................................................ ............................................................................

Application:

Cutting of slabs,tiles,clay tubes,

roofing tiles,clinker,metal,steel, stainless steel,plastic, rubber etc.

............................................................................

Characteristics:

Medium hard cutting disc with excellent life . It doesn't make work piece burnt , and have smooth finished cutting edges.

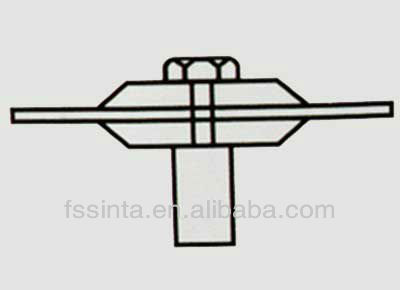

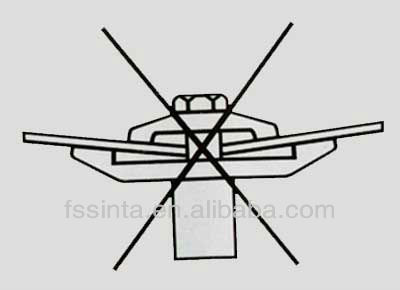

Installing system

Never use flanges of different diameter ,two flanges clamping a cutting and grinding tools must always have the same outside diameter and support area.

CORRECT

INCORRECT

Safety Guide

To make sure you have the right disc for the right job we disply the following icons on our products, labels and packing.

Before use, carefully read the safety guide for the proper use.

1. Always handle and store wheels carefully. Cutting-off wheels should be stacked horizontally and flat , preferably on a steel base plate.

2. Always visually inspect all wheels before mounting for possible damage in transportation.

3. Always use a safety guard and ensure that it is correctly positioned and securely fitted. It should cover at least one half of the wheel and protect the operator in the unlikely event of a wheel breakage.

NON-REINFORCED CUTTING-OFF WHEELS SHOULD ONLY BE USED ON FIXED MACHINES AND SHOULD BE CORRECTLY GUARDED.

4. Always switch “OFF” the power at supply source and / or remove the plug from the socket before changing the wheel.

5. Always ensure that the spindle speed of the machine does not exceed the operating speed marked on the wheel.

6. Always use the correct wheel mounting flages and ensure that they are undamaged, clean, and free from burrs.

7. Allow newly mounted wheels to run at operating speed, with the guard in place, for a reasonable time before cutting or grinding.

8. Always wear EYE PROTECTION.

9. Always wear appropriate safety clothing such as DUST MASK, GLOVES, EAR PROTECTION, OVERALLS AND SAFETY SHOES.

10. Always have machine speeds checked regularly, especially after maintenance or repair. Machines fitted with speed control devices(Governors), must be properly maintained at all times.

11. Check tension of driving belts , where fitted, on a regular basis. Belts must be kept tight

to ensure full power transmission.

12. Always secure the work piece firmly while it is being cut or grind.

13. Put portable machines in suitable cradles, when not being used, to avoid damage to the wheel.

14. Always use a portable machine in a comfortable position, where the work piece is well balanced and the machine is well supported.

15. Grind at an angle above 30 degrees to the work piece with a depressed center wheel.

16. Keep the working area around cutting and grinding operations clear. It is very dangerous if an operator trips and falls with an operating machine in his hands.

Key points for the best result

Hold your right angle grinder at 90° for cutting.

Package

Inner package: suitable quantity packed by polyester bag and box.

Outside package:

Workshop and equipment

Transport and load container